MFG. Process

SFT’s efficient and safe production line creates a number of high-quality products.

Our high technology production line meets the strict needs of the market. We are making efforts to create a comfortable plant environment and produce efficient and high-quality products.

Plant is equipped with the integrated process line (including hot forging) ensures mass production.

SFT Plant is equipped with all facilities necessary for mass production. In the Forging Workshop, forging formers are used for hot forging. Then products are manufactured on the integrated process line (consisting of Annealing Workshop, Shot Workshop and CNC Turning Workshop)

Processes

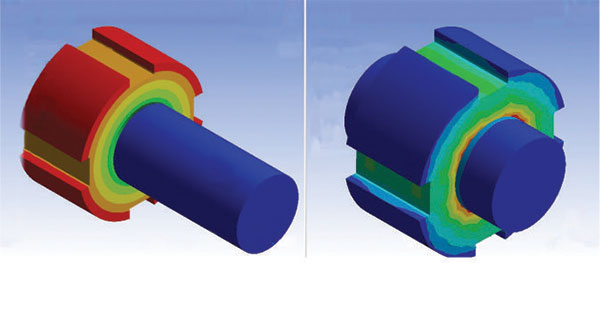

1. Dies Designing

Dies for ordered items are designed and manufactured.

2. Hot forging

Steel bars are heated with high frequency for precision molding.

3. Spheroidizing annealing

The automatically temperatureis controlled furnace.

4. Shot blast

Abrasive particles are shot to remove oxidized scales.

5. CNC turning

High-precision lathe turning by using a CNC turning machine.

6. Packing

At last packing is done and shipped as per Customer Requirements.